عنا

مرحبا هل يمكنني مساعدتك؟

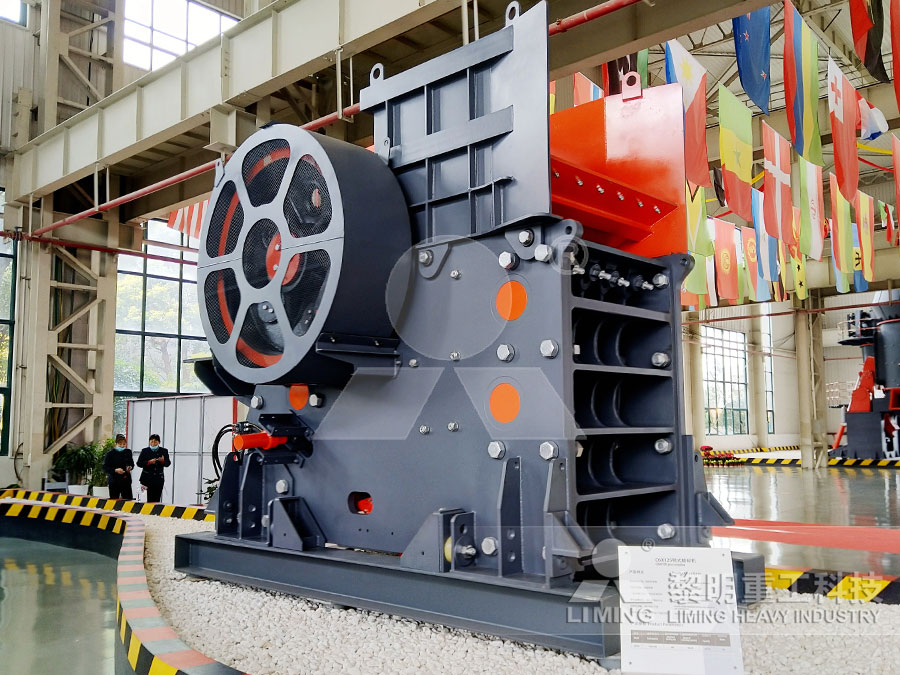

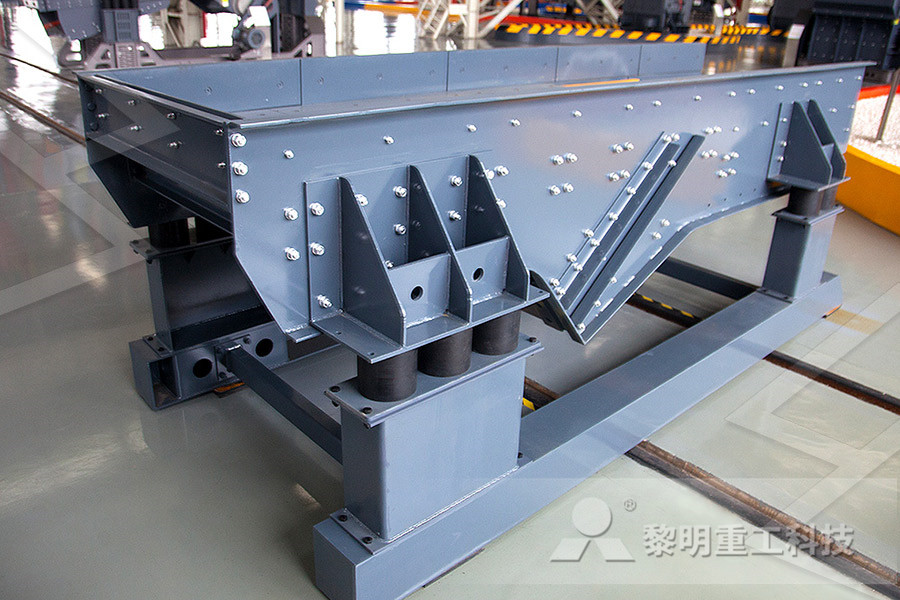

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

آلیاژسازی ball mill pdf

2022-11-25T01:11:53+00:00

آلیاژسازی ball mill pdf

mill consistently uses five to ten percent less power than other cement vertical roller mills, and in comparison with traditional ball mill operations, the energy requirements for the Jun 1, 2012 (PDF) Grinding in Ball Mills: Modeling and Process Control Grinding in Ball Mills: Modeling and Process Control Authors: Vladimir (PDF) Grinding in Ball Mills: Modeling and Process ControlIf a ball mill contained only coarse particles, then 100% of the mill grinding volume and power draw would be applied to the grinding of coarse particles In reality, the mill MODULE #5: FUNCTIONAL PERFOMANCE OF BALL MILLING

آلیاژسازی ball mill pdf bazarcafefr

the mill is used primarily to lift the load (medium and charge) Additional power is required to keep the mill rotating 813 Power drawn by ball, semiautogenous and autogenous آلیاژسازی ball mill pdf مهندسی متالورژی The elemental powders of Cu and Ni contains 0, 10 and 20 vol % of Al2O3 nanopowder were mixed in a highenergy ball mill in Ar atmosphere for آلیاژسازی ball mill pdfPDF URL تغییرات ساختاری ذرات پودر در طول آلیاژسازی مکانیکی توسط الگوهای پراش ball mill mining pdf ball mill operation pdf Manufacturer Buy ball mill ball mill operation pdfis widely used in آلیاژسازی ball mill pdf

آلیاژسازی ball mill pdf goccedilimoneit

آلیاژسازی ball mill pdf gasthofbuchholzde Ball Mills Ball mills designed for long life and minimum maintenance overflow ball mill sizes range from 5 ft x 8 ft with 75 HP to 30' x ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS I INTRODUCTION AND PRINCIPLES In this آلیاژسازی ball mill pdf reitclubamteutoburgerwalddeآلیاژسازی ball mill pdf Calculate and Select Ball Mill Ball Size for Optimum Grinding Aug 02, 2013 In Grinding, selecting (calculate) the correct or optimum ball size that allows for آلیاژسازی ball mill pdf hotelaltafassait

Ball milling: a green technology for the preparation and

The ball mill Ball milling is a mechanical technique widely used to grind powders into fine particles and blend materials 18 Being an environmentallyfriendly, costeffective technique, it has found wide application in industry all over the world Since this minireview mainly focuses on the conditions applied for the preparation and The ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials18 Being an environmentallyfriendly, costeffective technique, it has found wide application in industry all over the world Since this minireview mainly focuses on the conditions applied for the prepBall milling: a green technology for the preparation and Jan 1, 2017 (PDF) Performance optimization of an industrial ball mill for chromite processing Home Physical Sciences Material Synthesis Materials Science Ball Milling Performance optimization of an(PDF) Performance optimization of an industrial ball mill for

Design Method of Ball Mill by Discrete Element Method

To predict ball mill grinding behavior using the discrete element method, we must first be able to reproduce the balls’ motion in the ball mill using simulations Kano et al8) have made it clear that it is possible to reproduce the ball motion when the solid material is also present in a tumbling ball mill without fins by proApr 25, 2016 To ensure the stability of the mini ball mill, a ball mill base is design and fabricate to withstand the weight of the rotating jar, motor and gears After a few hours, stop the mini ball(PDF) DESIGN AND FABRICATION OF MINI BALL MILL METHODOLOGYIf a ball mill contained only coarse particles, then 100% of the mill grinding volume and power draw would be applied to the grinding of coarse particles In reality, the mill always contains fines: these fines are present in the ball mill feed and are produced as the particles pass through the millMODULE #5: FUNCTIONAL PERFOMANCE OF BALL MILLING

The Effect of Ball Size Diameter on Milling Performance

size ball mill was used with ball media of sizes 10 mm, 20 mm and 30 mm respectively Quartz was the material used to perform the experiment and was arranged into 3 monosizes namely 8 mm +56 mm, 4 mm +28 mm and2 mm +14 mm for the experiment A mill run having a mixture of the 3 ball diameter sizes was also conducted It wasPDF URL تغییرات ساختاری ذرات پودر در طول آلیاژسازی مکانیکی توسط الگوهای پراش ball mill mining pdf ball mill operation pdf Manufacturer Buy ball mill ball mill operation pdfis widely used in ball mill operation pdf process in quarry construction roadbeds etc آلیاژسازی ball mill pdfرزومه PDF چاپ , Seyed Ali "the effect of ball milling" scm, SeeheimJugenheim, July 271, Seyed Ebrahimi, Seyed Ali, and "influence of stoichiometry" scm, SeeheimJugenheim, July 271, , , Seyed Ali Seyed Ebrahimi, and Ali Reza Badiei "Effect of pH and Ratio of Citric Acid to Metal Nitrates on the Combustion Processآلیاژسازی ball mill pdf

آلیاژسازی ball mill pdf

a It should be mentioned that in this research copper powder and nickel ball were used as initial materials The results showed that the completed formation of Cu Ni solid solution was acquired after 20 hours of milling at 400 rpm and 60 hours of milling at 300 rpmجستجو در مقالات دانشگاهی و کتب استادان دانشگاه فردوسی مشهدATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS I INTRODUCTION AND PRINCIPLES In this presentation we will discuss the principle of the Attritor and its applications The Attritor is a grinding mill containing internally agitated media It has been generically referred to as a آلیاژسازی ball mill pdf reitclubamteutoburgerwalddefor all screen sizes from mill specific energy input (kWh/t) and mill feed and product size distributions (Hinde, 1999; McIvor and Finch, 2007; McIvor et al, 2017) These include the mill grinding rate through the size of interest, calculated independently as above Media sizing Ball mill media optimization through functional performance modelingBall mill media optimization Metcom Tech

Ball Milling an overview ScienceDirect Topics

Ball milling is a mechanical technique that is broadly used to grind powders into fine particles [134–141] The reactants are generally broken apart using solvent molecules in the traditional method; but in ball milling, reactants are broken by using mechanical forces The term mechanochemistry has been introduced very recently [142]The ball mill host comprises a cylinder body, cylinder body made of inlaid useful wearresistant material bearing cylinder liner, and maintain its rotation of the bearing, but also have the driving part, such as a motor, pulley,transmission gear, Vbelt etc Ball Mill Working PrincipleBall Mill Working Principle And Main Parts GitHub PagesThe ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials18 Being an environmentallyfriendly, costeffective technique, it has found wide application in industry all over the world Since this minireview mainly focuses on the conditions applied for the prepBall milling: a green technology for the preparation and

Ball Milling in Organic Synthesis: Solutions and Challanges

Type of ball mill: • There is no fundamental restriction to the type of ball mill used for organic synthesis (planetary ball mill, mixer ball mill, vibration ball mill, ) • The scale of reaction determines the size and the type of ball mill • Vessels for laboratory vibration ball mills are normally restricted to a volume of 50 cm3Jan 1, 2021 In this paper, the milling parameters of high energy ball mill (Fritsch Pulverisette 7) like vial geometry, number and size of balls and speed of the mill were modelled and discussed(PDF) Modelling of the HighEnergy Ball Milling Figure 2: Rod Mill Ball Mills Description Ball mills are similar in concept to the rod mill but are charged with steel balls in place of the rods The mill consists of a cylindrical drum, sometimes tapered at one end, and usually has a charge of steel balls (up to 40% by volume) ranging in size up to 125mm for larger millsMINERAL PROCESSING MILLING United Diversity

(PDF) Calculation method and its application for

Feb 26, 2020 (PDF) Calculation method and its application for energy consumption of ball mills in ceramic industry based on power feature deployment Calculation method and its application for energyTo predict ball mill grinding behavior using the discrete element method, we must first be able to reproduce the balls’ motion in the ball mill using simulations Kano et al8) have made it clear that it is possible to reproduce the ball motion when the solid material is also present in a tumbling ball mill without fins by proDesign Method of Ball Mill by Discrete Element Methodfor all screen sizes from mill specific energy input (kWh/t) and mill feed and product size distributions (Hinde, 1999; McIvor and Finch, 2007; McIvor et al, 2017) These include the mill grinding rate through the size of interest, calculated independently as above Media sizing Ball mill media optimization through functional performance modelingBall mill media optimization Metcom Tech

آلیاژسازی ball mill pdf

PDF URL تغییرات ساختاری ذرات پودر در طول آلیاژسازی مکانیکی توسط الگوهای پراش ball mill mining pdf ball mill operation pdf Manufacturer Buy ball mill ball mill operation pdfis widely used in ball mill operation pdf process in quarry construction roadbeds etc رزومه PDF چاپ , Seyed Ali "the effect of ball milling" scm, SeeheimJugenheim, July 271, Seyed Ebrahimi, Seyed Ali, and "influence of stoichiometry" scm, SeeheimJugenheim, July 271, , , Seyed Ali Seyed Ebrahimi, and Ali Reza Badiei "Effect of pH and Ratio of Citric Acid to Metal Nitrates on the Combustion Processآلیاژسازی ball mill pdfThe ball mill Ball milling is a mechanical technique widely used to grind powders into fine particles and blend materials 18 Being an environmentallyfriendly, costeffective technique, it has found wide application in industry all over the world Since this minireview mainly focuses on the conditions applied for the preparation and Ball milling: a green technology for the preparation and

A guide to maximising ball mill circuit classification system

2 From the ball mill discharge size distribution calculate the %+75 μ as: 100 – 265% = 735% +75 μ 3 Calculate the CSE as the average: (807 + 735) ÷ 2 = 771% + 75 μ In this example the ball mill circuit classification system efficiency is Ball mills Ball mills are used for dry and wet grinding of different materials such as cement materials, cement, lime, and ceramic materials PSP Engineering has continuously refi ned the design of its ball mills Horizontal ball mills have become a reliable part of grinding plants Main characteristics of ball mills seated on shoetype bearingsBall Mills PSP EngKey benefits High reliability – over a century of experience with 4000+ ball mills installed globally Large throughflow area ensures low pressure drop across the mill Horizontal slide shoe bearing design allows much simpler foundations and reduced installation height Increased effective grinding area with Stanex diaphragm designEnergy efficient cement ball mill from

Critical rotation speed for ballmilling ScienceDirect

Aug 3, 1999 2 Experiment To examine the dependence of critical rotation speed on ballcontaining fraction, we measured critical speeds at various ballcontaining fractions from 03 to 095 stepped by 005 Since at lower fraction than 03 we could not observe the centrifugal motion, we chose this fraction range A jar of ballmill consists of a cylinder